Everyone is forced to make changes in these unprecedented times. For dental labs, this means remaining flexible, and lowering operational costs, and adapting production to fill the demand for products outside the dental industry. Many labs are making this transition gracefully, using their cutting-edge digital manufacturing capabilities to increase efficiency and adaptability. Others are discovering new possibilities within the digital manufacturing space, using 3D printers to manufacture face shields, nasal swabs, and other necessities for the front lines of the pandemic. Still others are finding themselves forced to adapt 3D printing technology when they were previously hesitant to do so, and are discovering a new way of doing business, one that is more efficient, precise, and able to adapt to any situation.

One of the most recent labs to make the jump to digital manufacturing for their splints is Drake Precision Dental Lab. Based in Charlotte, North Carolina, Drake has delivered uncompromising quality, innovation, and aesthetics to dental practices across the nation since 1982. However, even nearly forty years of experience could not prepare Drake for the economic and cultural shock that is COVID-19. Adapting to this unprecedented event meant cutting labor costs, production costs, and increasing efficiency across the board. Fortunately, Drake found the perfect solution for their splint manufacturing in KeySplint Soft® Clear by Keystone Industries.

One of the most recent labs to make the jump to digital manufacturing for their splints is Drake Precision Dental Lab. Based in Charlotte, North Carolina, Drake has delivered uncompromising quality, innovation, and aesthetics to dental practices across the nation since 1982. However, even nearly forty years of experience could not prepare Drake for the economic and cultural shock that is COVID-19. Adapting to this unprecedented event meant cutting labor costs, production costs, and increasing efficiency across the board. Fortunately, Drake found the perfect solution for their splint manufacturing in KeySplint Soft® Clear by Keystone Industries.

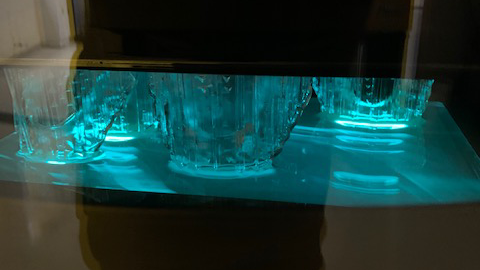

For the past two weeks, Drake Laboratories began producing nightguards exclusively through digital means. After taking a bit of time to dial in the perfect settings for their printer, Drake was able to produce about sixty nightguards in the first week and a half with minimal finishing, saving enormous amounts of time and labor costs.

Even though the transition was more abrupt than he would have like, Andre Theberge, the general manager of Drake Precision Dental Lab was convinced after just the first few days.

“We were always going to convert our splints to the Keystone material and this virus circumstance has forced us to do it cold turkey,” Theberge said, “I love it and will obviously never go back.”

During the transition, Drake had the opportunity to directly compare analog and digital bitesplint production methods. There was no contest. The time savings offered by digital production simply outclassed analog methods. What once took five days to manufacture can now be done in a single day.

During the transition, Drake had the opportunity to directly compare analog and digital bitesplint production methods. There was no contest. The time savings offered by digital production simply outclassed analog methods. What once took five days to manufacture can now be done in a single day.

However, the time savings was not the only benefit Drake found in switching to KeySplint Soft Clear. The material offered distinct advantages compared to traditional nightguards. The material is much more durable, and lacks the brittleness of traditional nightguards. This flexible quality is amplified when placed in a patient’s mouth, where the material flexes with the movement of a patient’s mouth, reducing wear and ensuring the longevity of the device.

Even with this flexibility, KeySplint Soft Clear remains rigid enough to act as a hard splint, providing superior protection and patient comfort. With KeySplint Soft Clear in their new workflow, Drake Precision Dental Labs has found a way forward that sets them up for success in the future.

Though the challenges facing us are unprecedented, and we must remain vigilant to maintain some semblance of physical and economic health, it is important to look for glimmers of light in the darkness. Stories like that of Drake Laboratories show us that although the challenges before us are steep, they are not insurmountable. We can adapt, we can survive, and when the crisis finally passes, we will emerge stronger than we ever were before. Keystone Industries is proud to stand behind you as we navigate these uncharted waters, and we will be with you on the other side, ready to work towards a brighter future.